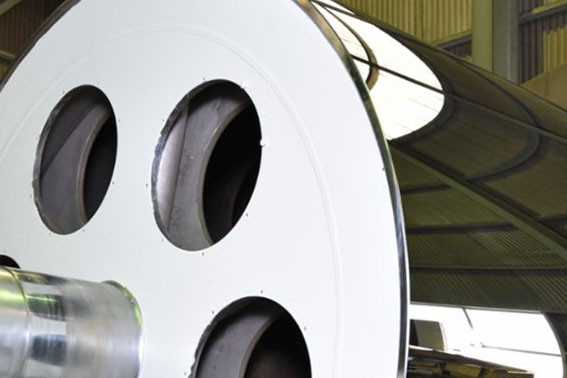

Hard chrome plating

Industrial chrome plating is widely used as a metal surface treatment technology to improve corrosion resistance, especially wear resistance.

The most important requirement for industrial plating is to apply a thick, uniform film with good adhesion to the substrate, and for this reason, chrome plating requires numerous work processes.

We are able to meet the diverse needs of our customers by utilizing our many years of experience and technological capabilities since our founding and by equipping our Okayama Plant with large-scale facilities.

High hardness

Hard chrome plating is usually the hardest of all electroplating processes and is much harder than nitrided copper, heat-treated copper, etc.

Abrasion resistance

This is a characteristic of hard chrome plating and is extremely good.

Corrosion resistance

Stable against inorganic acids except hydrochloric acid, hydrochloric acid, hydrofluoric acid, and highly concentrated sulfuric acid.

Anti-Brittlement

Heat treatment causes a rapid decrease in hardness, especially at temperatures above 200°C, where hydrogen is absorbed in the plating film and released, and at the same time decreases wear resistance.

Therefore, heat treatment to prevent hydrogen embrittlement of materials is performed at 150 to 200℃.