Electroless nickel plating

(Sankel Plating)

Plating obtained when the plated object is immersed in an aqueous solution containing nickel salt and hypophosphite (reducing agent). The electrons released by the oxidation of the reducing agent are transferred to nickel ions, depositing a nickel-phosphorus alloy film. Unlike ordinary electroplating, electroless nickel-phosphorus plating does not depend on electric power.

High hardness

Compared with ordinary electrolytic nickel plating (Vickers hardness: approx. 300), Sankel plating has a Vickers hardness of approx. 500 in the deposited state. Furthermore, Sankel plating hardens to almost the same hardness as industrial hard chrome (Vickers hardness: approx. 900-1000) by heat treatment at 400°C.

Uses

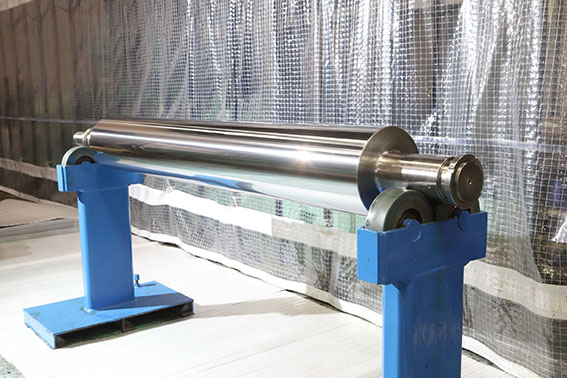

The corrosion and wear resistance of Sankel plating is appreciated by many customers, and applications include the following.

<Corrosion Resistance>

Compressor casing, roll inner surface

<Wear Resistance>

Various molds, plungers, cylinders, pump impellers, rings, etc.

Uniformity of film thickness

Sankeru plating is a plating method that uses a chemical reaction not electrodeposition. Therefore, the plating film of uniform thickness can be deposited even on products with complex shapes such as square products because the current distribution, which is usually a problem in electroplating, does not occur. The film thickness can be freely adjusted by time control.

Corrosion-resistant

is equivalent to that of industrial hard chrome plating by heat treatment. In the salt spray test (JIS Z2371), the rusting time from the material is more than 500 hours.